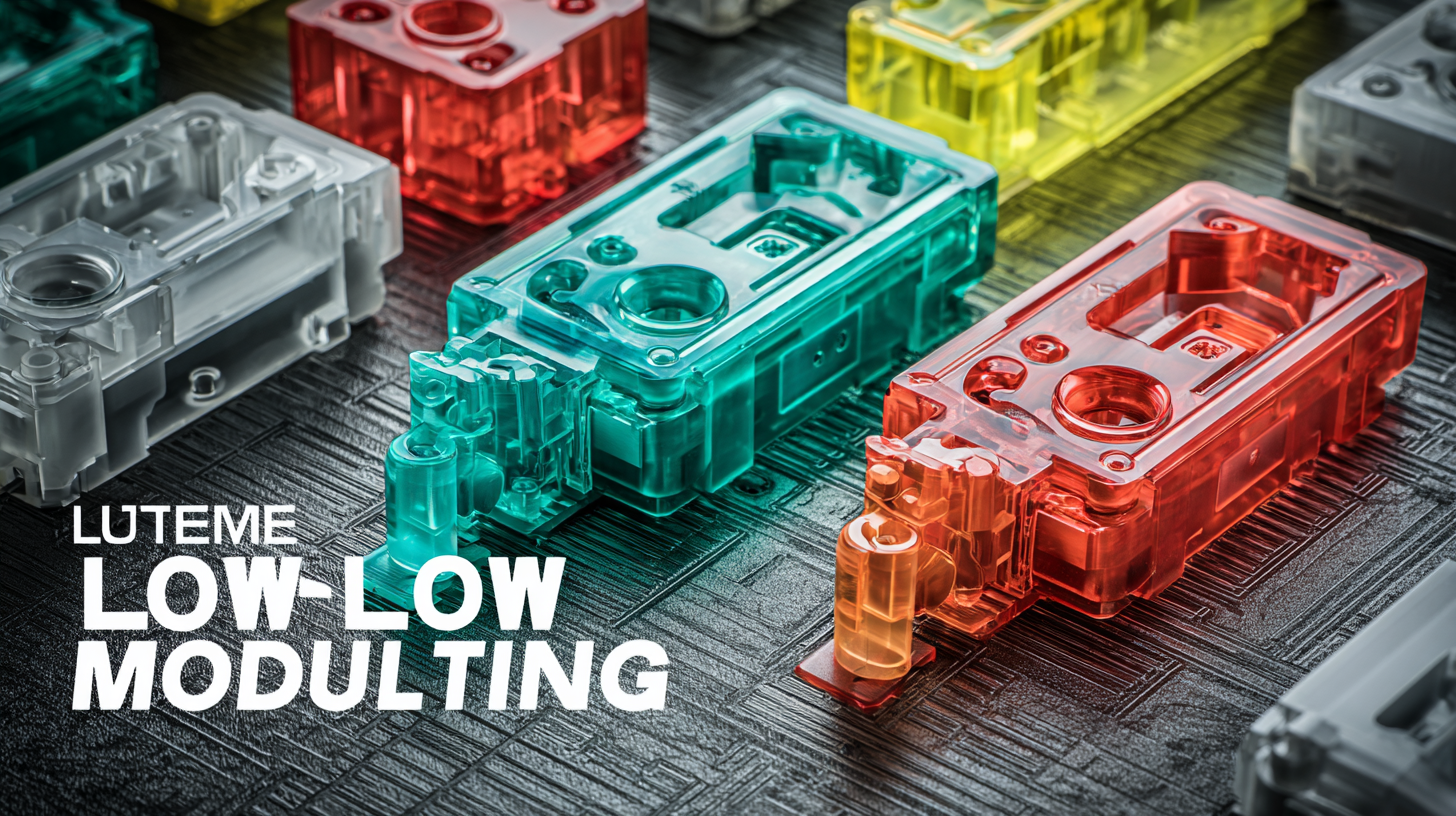

In today's competitive manufacturing landscape, businesses are constantly seeking innovative solutions to meet their production needs without compromising quality. Low volume injection moulding stands out as a highly effective technique that caters to companies looking to produce small batches of customized components while maintaining exceptional standards. This process not only allows for finer control over material characteristics and product design but also significantly reduces costs associated with high-volume production. With a focus on quality, "Made in China" products have become globally recognized for their efficiency and reliability, further enhancing the appeal of low volume injection moulding for businesses. In this ultimate guide, we will explore the key specifications of low volume injection moulding and delve into the top five benefits it offers, ensuring that your business stays ahead in a dynamic market.

Low volume injection moulding is a specialized manufacturing process that has gained traction among businesses looking for efficient production without the commitment of traditional large-scale moulding methods. This technique is ideal for producing small quantities of parts, typically ranging from a few dozen to several thousand units. By leveraging a tailored approach, companies can develop prototypes or finalize products with reduced lead times and costs compared to standard injection moulding.

One key advantage of low volume injection moulding is the ability to test designs and gather user feedback without significant financial investment. This flexibility allows businesses to iterate on their products rapidly, paving the way for innovative solutions that meet market demands. Additionally, low volume production often employs lower upfront costs in tooling and materials, making it a feasible option for startups and smaller enterprises aiming to bring their ideas to life while managing budgets effectively. This method not only enhances product development cycles but also decreases waste, contributing to a more sustainable manufacturing process.

| Specification | Value |

|---|---|

| Production Volume | 100 - 10,000 units |

| Material Options | ABS, Polycarbonate, Nylon, PETG |

| Lead Time | 2 - 4 weeks |

| Mold Material | Aluminum or Steel |

| Cost Efficiency | Reduced up-front costs compared to high-volume production |

When considering low volume injection moulding, key specifications play a critical role in ensuring optimal production outcomes. Factors such as material selection, cycle time, and mould design significantly impact both efficiency and product quality. According to a report by the International Journal of Advanced Manufacturing Technology, understanding these specifications can reduce production costs by up to 25% while meeting tight deadlines often required in today's fast-paced market.

Tip: Always evaluate the material properties needed for your components beforehand. Plastics like ABS or polycarbonate can present different behaviours during injection, influencing the final product's durability and surface finish.

Moreover, cycle time is another vital specification to analyze. Efficient mould design can enhance cycle speeds, with advanced techniques reportedly achieving reductions of up to 30% in cycle times, as noted in the latest industry studies. This efficiency is paramount for businesses aiming to scale production without sacrificing quality.

Tip: Collaborate closely with your moulding partner to ensure that the design encompasses both speed and accuracy; this can prevent costly delays and rework in the production phase.

Focusing on these key specifications allows businesses to not only optimize their processes but also to better meet customer demands in low volume production scenarios.

Low volume injection moulding is becoming increasingly popular among businesses looking to streamline their production processes. One of the top advantages of this method is its cost-effectiveness. By producing smaller quantities of parts, companies can significantly reduce initial tooling costs and mitigate the financial risk associated with large-scale production. This is particularly beneficial for startups and small businesses that may not have the budget for extensive manufacturing runs.

Another key benefit is the flexibility it offers. Low volume injection moulding allows businesses to iterate and refine their designs without the commitment to mass production. This can be crucial for companies looking to test market responses or refine their products based on consumer feedback. Tips for maximizing this advantage include conducting thorough market research before the moulding process and using rapid prototyping techniques to test and adjust designs quickly.

Additionally, low volume injection moulding can lead to faster time-to-market. With shorter production cycles, businesses can launch their products sooner, gaining a competitive edge. To enhance this benefit, consider collaborating closely with your injection moulding partner to ensure that communication is streamlined and any potential issues are addressed promptly. This proactive approach can help minimize delays and keep your project on track.

Low volume injection moulding has emerged as a game-changer in product development efficiency, enabling companies to accelerate their time-to-market significantly. According to a study by the American Society of Mechanical Engineers (ASME), businesses using low volume injection moulding can reduce their production lead times by up to 50%. This method allows for rapid prototyping, where modifications can be made swiftly based on market feedback, aligning closely with the agile methodologies embraced by product development teams.

Additionally, low volume injection moulding offers a cost-effective solution for small batch production, as firms can avoid the hefty investments associated with high-volume production molds. A report by Deloitte indicates that businesses utilizing this approach can save up to 30% on tooling costs, which is critical for startups and companies testing new products. By leveraging low volume injection moulding, organizations can not only optimize their resource allocation but also enhance product quality through better design iterations and faster validation processes.

In the realm of injection moulding, choosing between

low volume and high volume

production can significantly impact both cost and product quality. Low volume injection moulding

typically refers to the production of parts in quantities ranging from as few as 50 to several thousand units.

This method is particularly beneficial for startups and

small to medium-sized enterprises (SMEs) looking to test market viability without incurring the hefty costs associated with

high volume production, which often requires extensive tooling and larger factory setups.

According to a report by Smithers Pira, the demand for low volume manufacturing is projected to grow at a

CAGR of 4.5% through 2025, highlighting a shift in market preferences towards customized,

short-run production.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |