In the rapidly evolving landscape of manufacturing, the importance of "rapid prototyping sheet metal" has never been more pronounced. As industries gear up for the challenges of 2025, understanding the dynamics of market demand and technological advancements is crucial for maintaining a competitive edge. This blog explores the integration of effective after-sales support and maintenance strategies that can amplify the value derived from rapid prototyping sheet metal processes. By focusing on cost efficiency and superior customer service, companies can not only enhance their operational capabilities but also foster long-term relationships with clients. As we delve into the current market analysis and anticipate future trends, it becomes clear that a commitment to excellence in both product execution and support services will be key drivers of success in the realm of rapid prototyping sheet metal.

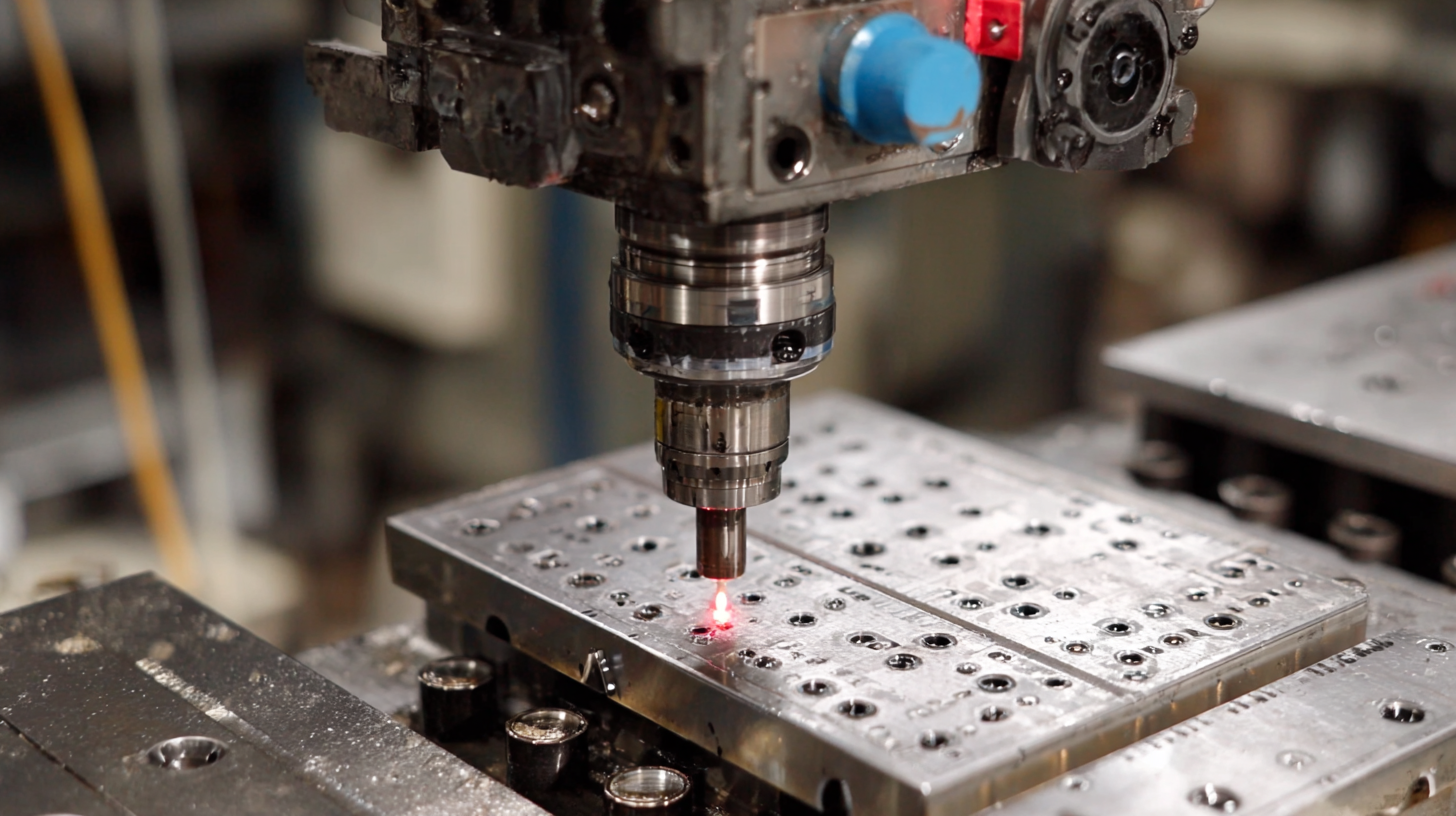

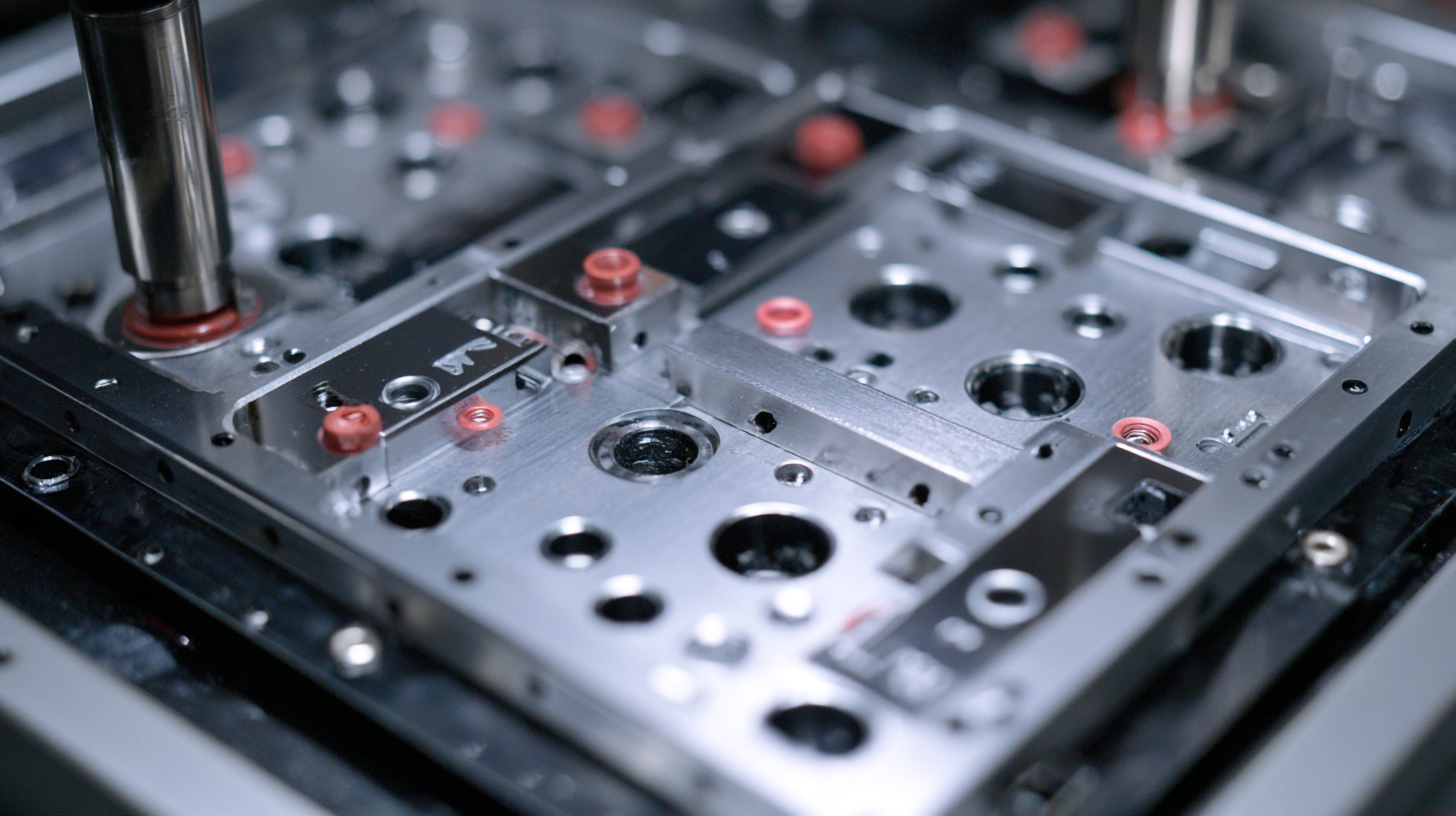

Rapid prototyping has revolutionized the landscape of sheet metal design by significantly shortening the product development cycle. According to a report by industry experts at Grand View Research, the rapid prototyping market is projected to reach USD 3.5 billion by 2025, driven by the increasing need for faster product development and innovation across various industries. Rapid prototyping techniques, such as 3D printing and CNC machining, allow engineers to create precise models, facilitating quick adjustments based on real-world testing and feedback. This iterative process not only enhances creativity but also reduces the time taken to bring products to market.

In the realm of sheet metal design, the importance of rapid prototyping cannot be overstated. Traditional methods often lead to extended lead times and high costs associated with manual tooling. However, with technologies like laser cutting and additive manufacturing integrated into prototyping workflows, companies can achieve a more cost-effective and efficient production process. Research from Wohlers Associates indicates that companies employing rapid prototyping have experienced up to 50% reductions in product development time, enabling them to respond more swiftly to market demands. This efficiency underscores the critical role rapid prototyping plays, ensuring that businesses not only meet customer expectations but also maintain a competitive edge in an increasingly fast-paced environment.

When exploring rapid prototyping services, quality after-sales support plays a crucial role in maximizing value. Key features to prioritize include prompt communication, which ensures that any issues or questions are addressed swiftly. This aspect not only fosters a strong relationship between the service provider and the client but also significantly reduces downtime. Look for providers that offer dedicated support teams who understand your specific needs and can provide tailored solutions.

When exploring rapid prototyping services, quality after-sales support plays a crucial role in maximizing value. Key features to prioritize include prompt communication, which ensures that any issues or questions are addressed swiftly. This aspect not only fosters a strong relationship between the service provider and the client but also significantly reduces downtime. Look for providers that offer dedicated support teams who understand your specific needs and can provide tailored solutions.

Another essential element is the transparent maintenance cost structure. Clients should seek out service providers who clearly outline their pricing models, preventing unexpected expenses down the road. A clear understanding of maintenance costs allows for better budgeting and can influence the overall success of a project. Furthermore, consider those who offer extended warranties or service packages that enhance the longevity of your prototypes.

Tips: Always request case studies or references to gauge the reliability of after-sales support. Additionally, establish a clear communication channel upfront to facilitate ongoing dialogue throughout the prototyping process. Setting these expectations early on can lead to a more efficient and satisfactory experience.

In the rapidly evolving landscape of rapid prototyping, the importance of maintenance cost efficiency cannot be overstated. According to a report from Wohlers Associates, companies can save up to 30% on operational costs by implementing effective after-sales support and maintenance strategies. This highlights the potential for significant financial benefits that can be derived from focusing on maintenance processes throughout the lifecycle of a rapid prototyping project.

One effective strategy for reducing maintenance costs is to invest in high-quality materials and components during the initial prototyping phase. Research from the Society of Manufacturing Engineers indicates that up to 60% of failure costs can be attributed to poor material choices. By ensuring that the prototype is built with superior-grade sheet metal, manufacturers not only enhance the durability of their products but also minimize the amount spent on repairs and replacements post-launch. Furthermore, leveraging advanced monitoring technologies can provide real-time data on equipment performance, enabling proactive maintenance and thereby reducing the frequency and cost of unplanned downtime, which is often cited as a major driver of maintenance expenses in production environments.

In today's competitive landscape, enhancing prototyping service efficiency hinges significantly on integrating customer feedback. A study from an industry research group reveals that companies adept at incorporating customer insights see a 20% increase in product development speed and a 30% reduction in prototypes' revision cycles. This is particularly relevant in rapid prototyping of sheet metal, where feedback loops can refine designs before full-scale production, ensuring that final products meet and exceed customer expectations.

Furthermore, the implementation of AI in customer experience has revolutionized how businesses interact with their clients. AI chatbots, for instance, can analyze customer inquiries and preferences in real-time, providing tailored support that enhances satisfaction. According to a survey, businesses that leverage AI tools report a 40% improvement in response times, directly contributing to higher customer retention rates. As frictionless communication becomes essential, companies that prioritize effective feedback mechanisms and innovative customer service strategies will undoubtedly outperform their peers in the market.

This chart illustrates the evaluation scores for various factors impacting the efficiency of rapid prototyping services. Customer feedback and after sales support play critical roles in maximizing value, while maintenance cost efficiency also contributes significantly to overall service efficiency.

In the rapidly evolving landscape of manufacturing, the role of rapid prototyping, particularly in sheet metal fabrication, has become critical in reducing lead times and optimizing costs. A recent report from the SME reveals that companies implementing effective prototyping solutions can see their time-to-market reduced by up to 40%. This significant improvement is largely attributed to the use of advanced technologies and superior after-sales support, which ensures that the transition from prototype to production is seamless and efficient.

Case studies illustrate the tangible benefits of these cost-effective prototyping solutions. For instance, a leading automotive manufacturer adopted a rapid prototyping approach that led to a 30% reduction in prototype development costs. This was achieved through streamlined processes and enhanced collaboration with suppliers, demonstrating how investing in robust after-sales support can drive not only efficiency but also innovation.

Drawing from the data, businesses that prioritize maintenance and consistent support can achieve a 50% increase in operational efficiency, making them more competitive in a crowded market. Such outcomes emphasize that successful implementation isn't merely about technology; it also hinges on strategic partnerships and ongoing support.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |