In today's rapidly evolving marketplace, the importance of high-quality rubber prototyping cannot be overstated, particularly as businesses seek to harness innovative solutions that meet diverse consumer demands. This blog explores the unique characteristics and applications of various product types within the realm of rubber prototyping, emphasizing how Chinese innovation is setting new benchmarks in quality assurance. By delving into the distinct features of different rubber products and their practical uses, we aim to provide a comprehensive guide that highlights the essential role of rubber prototyping in global sales. Understanding these nuances not only facilitates informed decision-making but also positions businesses to leverage cutting-edge techniques and materials, ultimately enhancing their competitive edge in the industry.

Leveraging Chinese innovation is a key driver for enhancing rubber prototyping quality, presenting significant advantages in the global market. As China advances its capabilities in various industrial sectors, including biotechnology and intelligent manufacturing, companies that utilize Chinese methods in rubber prototyping can expect higher efficiency and superior quality. Recent data indicates that China's investment in R&D has soared, with a notable increase in domestic patents, highlighting the country's commitment to innovation. This shift allows companies to access cutting-edge technologies that enhance the development and production processes in rubber prototyping.

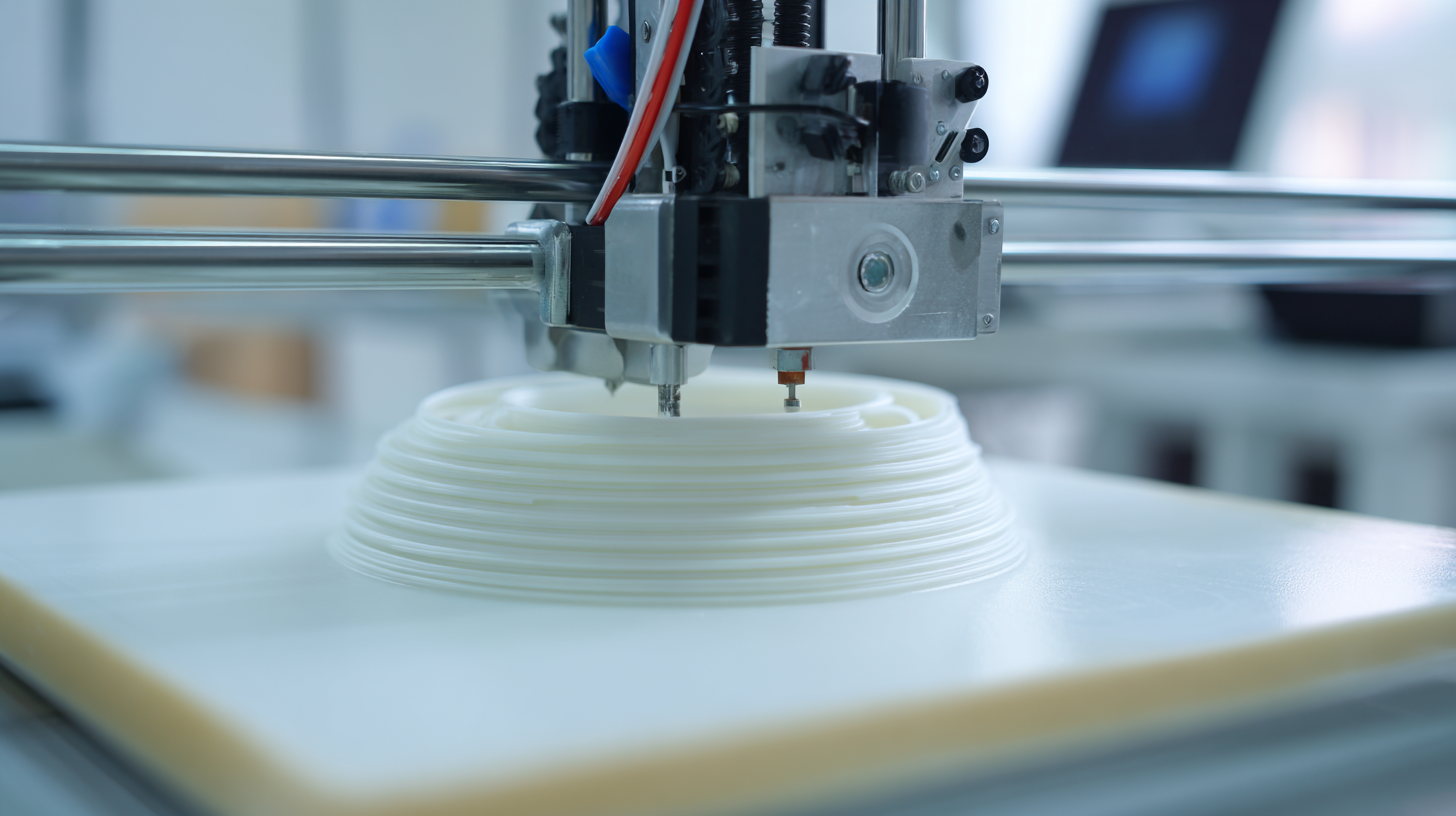

Furthermore, the integration of advanced manufacturing techniques, such as 3D printing, is reshaping the rubber industry landscape. Companies that have adopted these innovations report a 20-30% reduction in production time and costs while significantly improving product consistency and performance. The rapid evolution of China's rubber manufacturing capabilities not only supports better quality assurance but also fosters greater brand loyalty among consumers. As firms continue to harness these innovative practices, they position themselves strategically in the competitive Asian and global markets, ensuring sustainable growth and resilience in a fast-paced economic environment.

The evolution of advanced manufacturing technologies is significantly impacting global rubber sales trends, particularly as industries increasingly prioritize quality assurance in prototyping processes. According to a recent market analysis, the industrial rubber market is projected to grow steadily, reaching a valuation of USD 39.41 billion by 2033, progressing from USD 28.80 billion in 2025. This growth reflects an increasing demand driven by innovations in rubber processing techniques that enhance product quality and consistency.

Furthermore, the global formic acid market is expected to grow at a CAGR of 9.53%, with anticipated revenues reaching USD 5,240 million by 2033. This signifies a robust demand for components crucial in various applications, including rubber manufacturing. As companies adopt cutting-edge manufacturing technologies, they are not only boosting production efficiency but also achieving superior quality assurance in their rubber products, thereby aligning with the heightened expectations of consumers and industries alike. The integration of these advanced technologies offers a pathway to maintaining a competitive edge in an increasingly globalized marketplace.

In the realm of rubber prototyping, the significance of robust quality assurance processes cannot be overstated. Streamlined quality assurance not only fosters product reliability but also enhances the overall efficiency of the production cycle. By integrating advanced testing techniques and regular assessments, manufacturers can detect and address potential issues before they escalate, ensuring that every prototype meets stringent standards. This proactive approach not only minimizes wastage but also bolsters customer confidence in the final products.

Moreover, the infusion of Chinese innovation into these quality assurance processes is pivotal. With cutting-edge technology and sophisticated methodologies, Chinese firms are setting new benchmarks in the industry. For instance, automated inspection systems powered by artificial intelligence can provide real-time feedback on prototyping quality, allowing for immediate corrections. This level of precision ensures that the final products align with both international standards and customer expectations, making robustness a hallmark of Chinese rubber prototyping. By harnessing these innovations, businesses can optimize their quality assurance frameworks, resulting in superior, reliable offerings that cater to global markets.

In the rapidly evolving rubber industry, integrating sustainable practices is no longer an option but a necessity for companies seeking to enhance their competitive advantage. By prioritizing environmental responsibility, businesses can not only meet the increasing consumer demand for eco-friendly products but also streamline their production processes. Sustainable practices such as utilizing renewable materials, adopting energy-efficient technologies, and implementing waste-reduction strategies are crucial in minimizing the carbon footprint associated with rubber production.

Moreover, the role of innovation cannot be overlooked when discussing sustainability. Chinese companies, renowned for their innovative approaches, have started to seamlessly blend cutting-edge technologies with green practices. This combination ensures high-quality rubber prototyping while reducing environmental impacts. For instance, the development of new biodegradable compounds and eco-conscious manufacturing techniques allows companies to deliver superior products that appeal to a growing market of environmentally-conscious consumers, thus positioning them favorably against competitors.

| Region | Market Size (Million USD) | Growth Rate (%) | Sustainable Practices Adoption (%) | Innovative Technologies Used (%) |

|---|---|---|---|---|

| Asia-Pacific | 4500 | 6.5 | 75 | 80 |

| North America | 3200 | 4.2 | 65 | 70 |

| Europe | 2800 | 5.0 | 70 | 75 |

| Latin America | 1500 | 3.8 | 50 | 60 |

| Middle East & Africa | 1000 | 2.5 | 45 | 55 |

In the realm of rubber prototyping, innovation is dictated not just by creativity but also by measurable effectiveness. As companies strive to optimize their production processes, key metrics such as cycle time, material efficiency, and defect rates become essential indicators of success. By closely monitoring these metrics, businesses can ensure that their innovations lead to tangible improvements in quality assurance, thereby positioning themselves competitively in the global market.

To enhance your rubber prototyping quality assurance, consider implementing these tips: first, leverage advanced data analytics to track and analyze production metrics in real-time. This allows for quick pivots in strategy to address any inefficiencies. Secondly, foster collaboration between design and manufacturing teams to streamline the prototyping process, ensuring that innovations are feasible and cost-effective. Lastly, always seek feedback from end-users to refine the prototypes further, creating a continuous loop of improvement that drives innovation-based success.

As the industry embraces sustainable building materials, integrating these patterns into rubber prototyping can lead to new avenues for performance enhancement and environmental responsibility. Emphasizing innovation not only aligns with current trends but also secures a forward-thinking approach in a competitive landscape. By adequately assessing and applying key metrics, businesses can truly revolutionize their practices while prioritizing quality and sustainability.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |