In the rapidly evolving landscape of manufacturing, the demand for high-quality plastic prototypes has surged, particularly in the context of China's robust production capabilities. As we approach 2025, a comprehensive market analysis reveals the trends, challenges, and opportunities that define this sector. This blog will delve into the intricacies of plastic prototype manufacturing, highlighting not only the technical advancements but also the strategic approaches businesses can adopt to optimize their processes. From innovative design techniques to efficient production methods, this exploration aims to provide actionable insights for industry leaders and market newcomers alike. Join us as we navigate the future of plastic prototyping and uncover how to leverage China's manufacturing prowess for unparalleled product development.

In manufacturing, high-quality plastic prototypes play a crucial role in the development process, ensuring that products meet specifications and function effectively from the outset. Recent insights into quality assurance in micro moulding emphasize the need for rigorous testing and validation methods to avoid costly mistakes further down the production line. As reported by industry experts, effective quality assurance can significantly enhance the reliability of products, allowing manufacturers to respond swiftly to market demands.

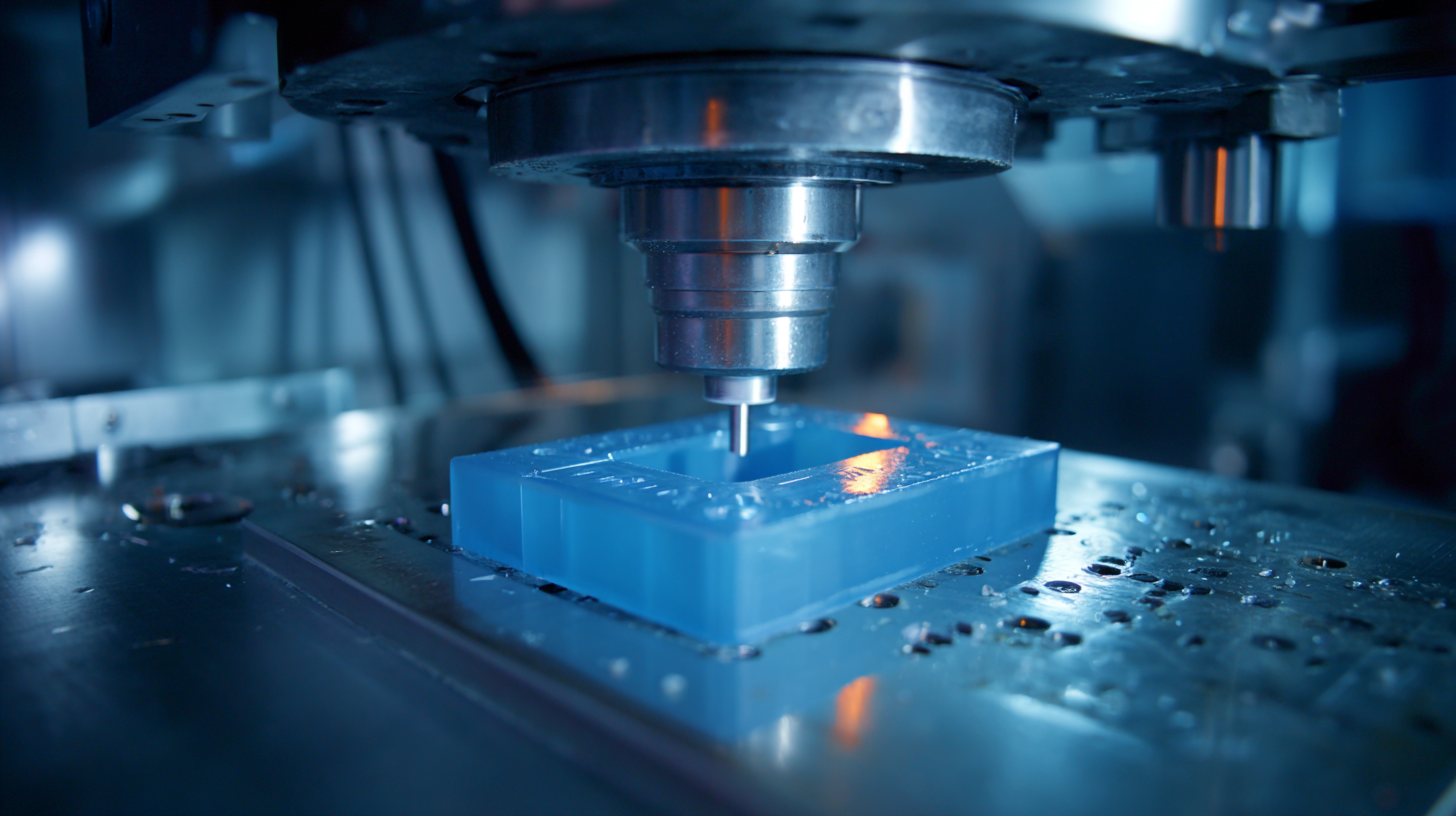

When considering plastic prototyping, one key tip is to leverage advanced manufacturing technologies such as additive manufacturing, which has seen substantial growth in sectors like aerospace and automotive. According to a recent survey of industry executives, 2025 is expected to bring significant innovations, especially in the integration of sustainable materials. Utilizing recycled materials in prototyping can also contribute to a more environmentally-friendly approach, addressing the pressing need for sustainable manufacturing solutions.

Another important aspect is the selection of a capable prototyping service provider. With many rapid prototyping companies emerging in China, it is essential to evaluate their technology capabilities and customer support. Engaging with a provider skilled in precision manufacturing can not only enhance the quality of your prototypes but also streamline the overall development process, leading to faster time-to-market and ultimately, higher customer satisfaction.

Sourcing plastic prototypes from China offers numerous key benefits for global businesses aiming to enhance their product development processes. First and foremost, the manufacturing capabilities in China are unmatched, providing access to advanced technology and skilled labor. This combination allows companies to produce high-quality prototypes that can be tested and refined efficiently, ultimately speeding up time-to-market. Additionally, with a vast network of suppliers and manufacturers, businesses can easily scale production based on demand, minimizing the risks associated with overproduction and inventory costs.

Another significant advantage is cost-effectiveness. China's established manufacturing infrastructure leads to lower production costs, enabling companies to allocate resources more effectively within their supply chains. This financial efficiency not only makes it easier for businesses to invest in innovation but also allows them to offer competitive pricing for their final products. Furthermore, with the growing trend of digital communication and logistics advancements, managing production remotely has never been easier, facilitating seamless collaboration between global businesses and Chinese manufacturers.

When selecting the right manufacturing partner in China for high-quality plastic prototypes, it's crucial to take a systematic approach. According to a 2021 report by Deloitte, nearly 61% of companies experienced challenges in supplier selection, underscoring the importance of a well-defined process. Start by assessing potential partners based on their industry certifications, production capabilities, and previous client feedback. Look for ISO 9001 certification or similar quality management certifications, as these are indicators of commitment to quality assurance.

Additionally, consider the geographical location of the manufacturing partner. A report from the Boston Consulting Group indicates that manufacturers located in regions closer to major logistics hubs can reduce shipping times and costs by up to 20%. Conducting site visits and audits can further ensure that the operations align with your quality expectations and production timelines. Remember, clear communication channels and a strong understanding of intellectual property regulations are also vital in building a productive partnership with a Chinese manufacturing company.

| Criteria | Importance | Recommended Score (1-5) | Notes |

|---|---|---|---|

| Manufacturing Experience | High | 4 | Look for at least 5 years in the industry. |

| Quality Control Standards | Critical | 5 | ISO certifications are a must. |

| Production Capacity | High | 4 | Ensure they can meet your order volume. |

| Technical Expertise | High | 5 | Check for engineering support and R&D capabilities. |

| Communication Skills | Important | 4 | Effective communication is key to project success. |

| Cost Effectiveness | Moderate | 3 | Compare quotes but beware of low-quality trade-offs. |

Effective communication is crucial when engaging with a Chinese prototype manufacturer, particularly as China continues to solidify its position as a leader in high-quality manufacturing. Understanding cultural nuances and business practices can significantly enhance the communication process. For instance, it’s beneficial to establish clear expectations regarding quality standards and timelines. Providing detailed specifications and examples can help bridge any gaps in understanding and ensure both parties are aligned throughout the prototype development process.

Another important aspect is the use of visual aids and tools. Given that China is at the forefront of innovative manufacturing processes, employing diagrams, sketches, or even physical samples can facilitate a more productive dialogue. Moreover, be mindful of the time difference and regional holidays, as these factors can influence response times and project timelines. Building a strong relationship based on mutual respect and open dialogue will not only aid in effective communication but also foster collaboration that can lead to exceptional prototype outcomes.

In the realm of prototype manufacturing, quality assurance practices are paramount, especially when sourcing from China. Chinese manufacturers are increasingly recognized for their capabilities in producing high-quality plastic prototypes, but understanding their quality assurance process is essential for ensuring that the final products meet global standards. Typically, these manufacturers implement rigorous testing protocols throughout the production cycle, encompassing everything from initial material selection to final product inspection. This includes evaluating the mechanical properties of plastics, conducting surface quality assessments, and adhering to international safety and compliance standards.

Moreover, collaboration between manufacturers and clients plays a crucial role in quality assurance. Many Chinese companies actively involve clients in the quality assurance process, ensuring that customer expectations are met from the outset. This can include everything from prototype design reviews to real-time adjustments during manufacturing. By fostering a transparent communication channel, manufacturers can address potential quality issues proactively, thereby enhancing the reliability of the prototypes produced.

As a result, companies looking for plastic prototypes can expect a meticulously managed manufacturing process that prioritizes quality, ultimately leading to superior end products that meet their specifications.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |