In an era where innovation accelerates at breakneck speed, the quest for efficient and high-quality plastic prototypes has become paramount across various industries. According to a recent report by the MarketsandMarkets research group, the global rapid prototyping market is projected to reach $2.96 billion by 2026, driven by advancements in technology and the demand for faster product development cycles. As companies strive to innovate and gain a competitive edge, the ability to create robust plastic prototypes rapidly and cost-effectively is transforming product design and manufacturing processes.

In an era where innovation accelerates at breakneck speed, the quest for efficient and high-quality plastic prototypes has become paramount across various industries. According to a recent report by the MarketsandMarkets research group, the global rapid prototyping market is projected to reach $2.96 billion by 2026, driven by advancements in technology and the demand for faster product development cycles. As companies strive to innovate and gain a competitive edge, the ability to create robust plastic prototypes rapidly and cost-effectively is transforming product design and manufacturing processes.

This surge in demand has prompted significant investments in materials and methodologies that enhance the durability and accuracy of prototypes, ultimately revolutionizing tomorrow’s manufacturing landscape. Emphasizing solutions tailored for effective plastic prototype development will be key to navigating the future of product design and fostering growth in various sectors.

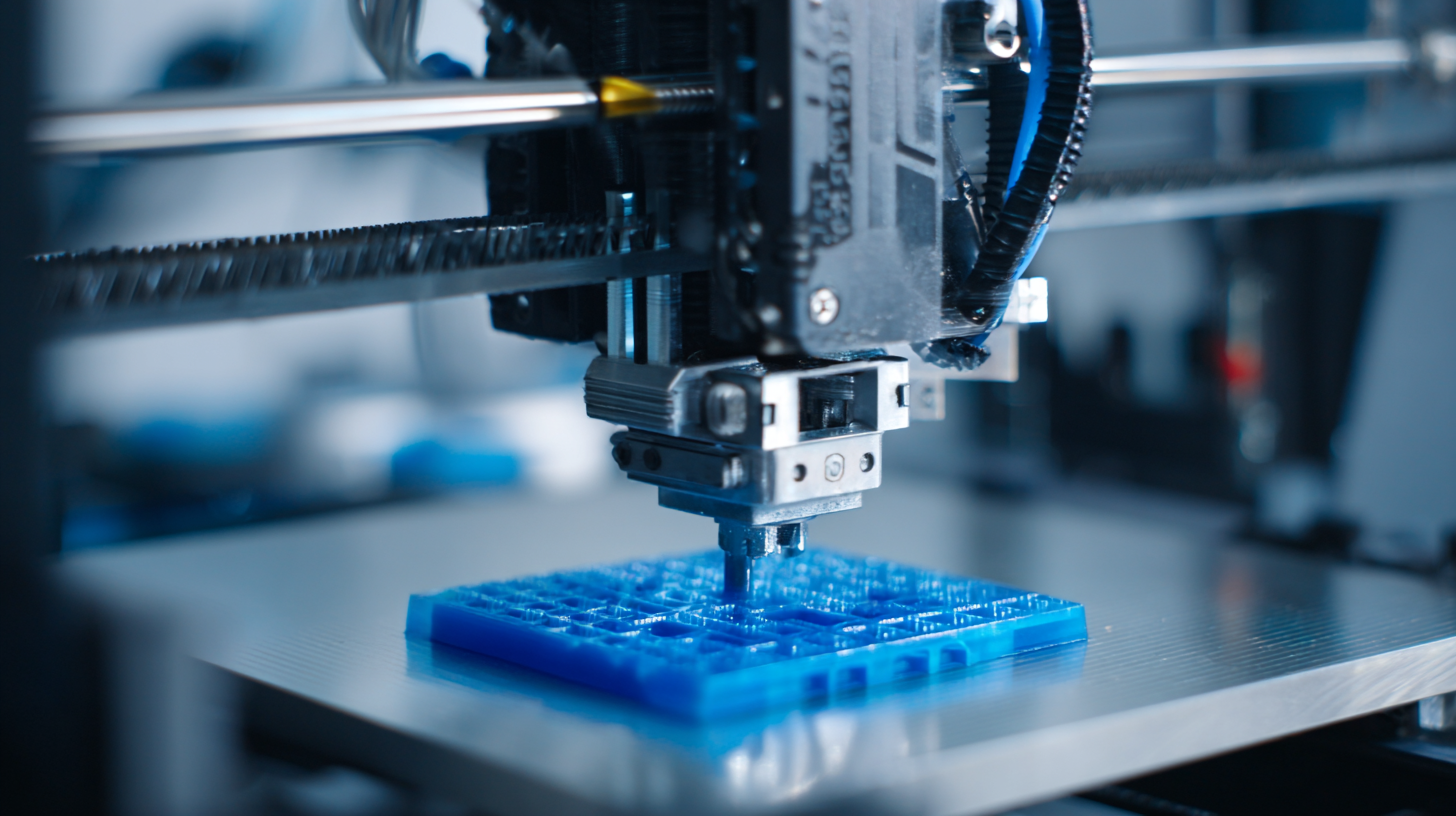

The importance of high-quality plastic prototypes in modern manufacturing cannot be overstated. As industries evolve, the demand for precision and functionality in prototyping has grown exponentially. High-quality prototypes serve as critical tools for testing designs, fitting parts, and assessing performance before full-scale production. By utilizing advanced techniques such as 3D printing and injection molding, manufacturers can create prototypes that closely resemble the final product, ensuring that any potential issues are identified early in the process.

Moreover, high-quality plastic prototypes facilitate enhanced collaboration among design teams, engineers, and stakeholders. By providing tangible models for evaluation, these prototypes allow for concrete feedback and iterative improvement. This collaborative approach not only speeds up the development cycle but also reduces costs associated with reworking designs after they have gone into production. As businesses strive for innovation and competitive advantage, investing in high-quality plastic prototypes becomes essential for achieving successful outcomes and meeting market demands.

In the rapidly evolving landscape of plastic prototype production, quality remains paramount. Key industry standards play a crucial role in defining what constitutes a high-quality prototype. ISO 9001 certification is a benchmark that ensures manufacturers adhere to quality management principles, ultimately leading to an increase in customer satisfaction. Furthermore, adherence to ASTM standards helps in assessing the performance and durability of plastic materials, which is essential for prototypes intended for end-use applications.

Tip: When selecting a supplier for plastic prototypes, always verify their certifications and adherence to industry standards. This ensures that the prototypes will not only meet your design specifications but will also perform effectively in practical scenarios.

Additionally, implementing a robust quality control process throughout the production phase can significantly impact the final product's reliability. Employing techniques such as Statistical Process Control (SPC) allows manufacturers to monitor key variables, minimizing defects and enhancing overall product quality.

Tip: Conduct regular audits of the production processes and materials used, as this can help identify potential issues early and maintain the high standards required for successful prototype development.

| Quality Standard | Description | Importance | Typical Applications |

|---|---|---|---|

| ISO 9001 | Quality management systems | Ensures consistency in quality and improvement in customer satisfaction | General manufacturing, automotive parts |

| ASTM D638 | Standard test method for tensile properties of plastics | Evaluates the strength and elasticity of plastic materials | Prototyping, medical devices |

| ISO 13485 | Quality management for medical devices | Ensures compliance with regulatory requirements | Medical applications, wearable technology |

| UL Certification | Safety standards for products | Indicates safety and reliability for consumer trust | Electronics, household appliances |

| REACH | Regulation for chemicals and their safe use | Ensures protection of human health and the environment | All industries using chemical substances |

The landscape of plastic prototyping is undergoing a transformative shift, largely influenced by innovative technologies that are redefining the production process. According to a recent report by MarketsandMarkets, the global plastic prototyping market is projected to reach $7.4 billion by 2025, growing at a CAGR of 8.6% from 2020. This surge is driven by advancements in additive manufacturing and 3D printing technologies that allow for more rapid and cost-effective prototyping solutions, significantly reducing the time from concept to production.

Furthermore, the incorporation of AI and machine learning in the prototyping stage enhances design precision and functionality. A study from Deloitte found that companies investing in these technologies tend to see a 30% increase in product development efficiency. With the ability to simulate real-world conditions digitally, designers can iterate faster and with greater accuracy, ensuring that prototypes meet high-quality standards before entering mass production. As these technologies continue to evolve, their impact on the future of plastic prototyping will be profound, enabling industries to push the boundaries of innovation.

As the demand for rapid prototyping increases, the focus on sustainability in plastic prototyping must take center stage. Industries are gradually recognizing the importance of adopting eco-friendly practices that not only reduce waste but also capitalize on innovative materials. Utilizing bioplastics and recycled materials can substantially decrease the carbon footprint of prototypes, making them viable options for manufacturers aiming to align with environmental standards.

Tip 1: When selecting materials for prototyping, consider biodegradable options to minimize environmental impact. These materials not only perform effectively but also offer a sustainable alternative to traditional plastics.

To further enhance sustainability, implementing a closed-loop production cycle is essential. This involves recycling prototypes back into the production process, allowing companies to reuse materials and reduce the need for new plastics. The integration of digital printing technology can streamline this process, enabling on-demand production and minimizing excess inventory.

Tip 2: Embrace digital tools for prototyping to optimize the use of materials, thus reducing waste and energy consumption. By refining designs digitally before physical production, you can ensure that only the necessary resources are utilized, contributing to a more sustainable manufacturing model.

In the rapidly evolving landscape of prototyping, the adherence to industry standards plays a pivotal role in achieving precision and consistency in high-quality plastic prototypes. These standards serve as a benchmark for manufacturers, ensuring that every prototype meets specific material and dimensional requirements. By implementing established guidelines, companies can significantly reduce the variability that often plagues the prototyping process, leading to more reliable and repeatable results.

Moreover, industry standards foster collaboration between different stakeholders in the prototyping ecosystem. Designers, engineers, and manufacturers can communicate more effectively when they operate within a common framework. This alignment not only enhances the quality of the prototypes but also streamlines the development process, allowing teams to focus on innovation instead of troubleshooting inconsistencies. Ultimately, the commitment to industry standards not only elevates the quality of plastic prototypes but also drives the entire industry towards a future of greater advancements and sustainable practices.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |