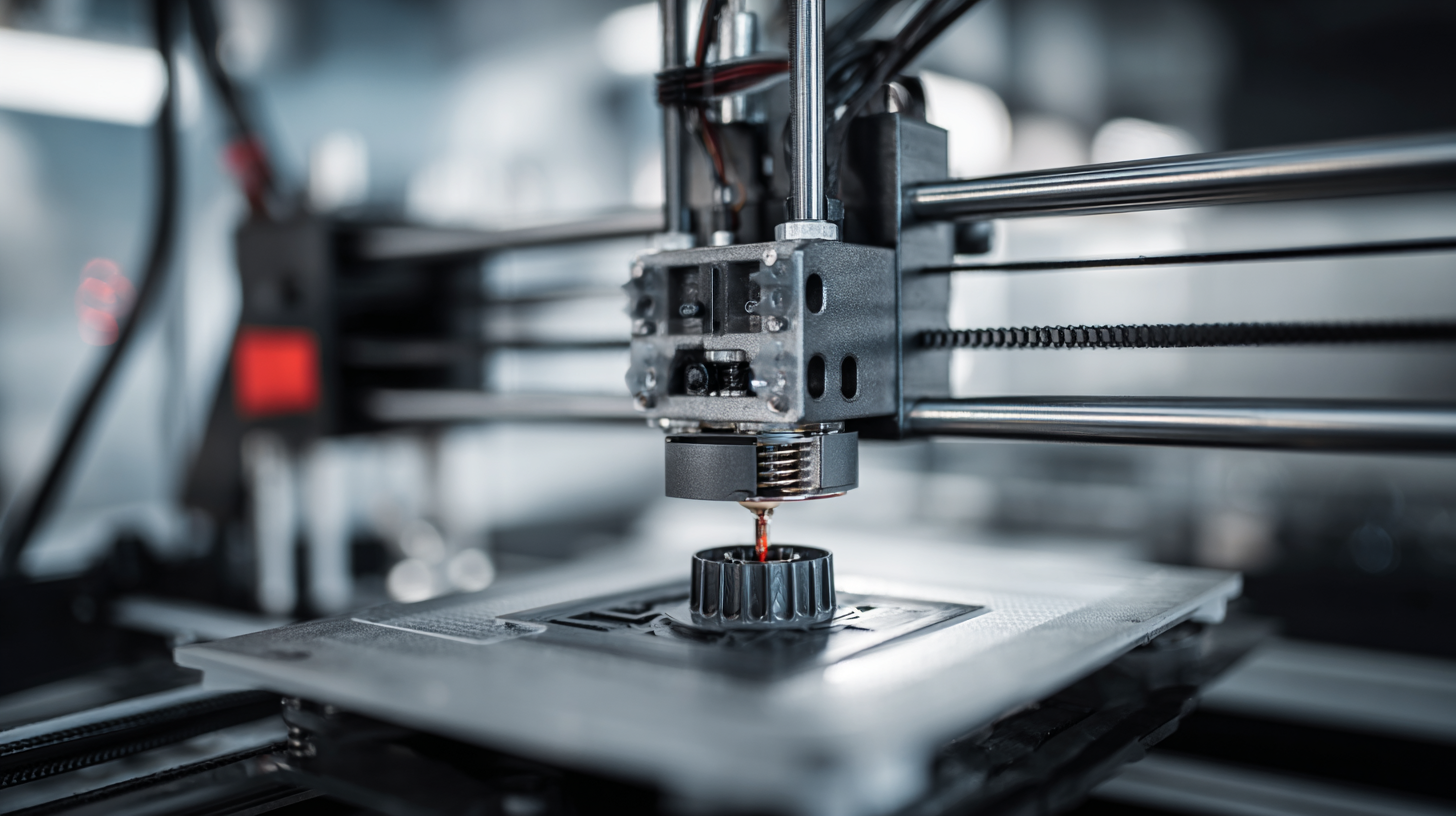

In the rapidly evolving world of product development, finding quality suppliers for fast prototyping solutions is crucial for businesses aiming to bring innovative ideas to market efficiently. Fast prototyping allows companies to create and test models quickly, facilitating iterative design processes and reducing time-to-market. However, selecting the right supplier can be a daunting task due to the vast array of options available, each claiming to offer the best services. It's essential to understand what makes a supplier stand out in the realm of fast prototyping, from their capability in advanced manufacturing techniques to their ability to meet project timelines and budget constraints.

This blog will guide you through essential criteria to consider when searching for the best suppliers, ensuring that you make informed decisions that will enhance your prototyping journey and ultimately lead to successful product launches.

When selecting quality suppliers for fast prototyping solutions, several key factors come into play that can significantly impact the overall success of a project. First and foremost, assessing the supplier's industry experience and expertise is crucial. A seasoned supplier will not only understand the nuances of the prototyping process but also have the technical capabilities to handle complex projects. This experience often translates into higher precision, shorter lead times, and better problem-solving skills when challenges arise.

When selecting quality suppliers for fast prototyping solutions, several key factors come into play that can significantly impact the overall success of a project. First and foremost, assessing the supplier's industry experience and expertise is crucial. A seasoned supplier will not only understand the nuances of the prototyping process but also have the technical capabilities to handle complex projects. This experience often translates into higher precision, shorter lead times, and better problem-solving skills when challenges arise.

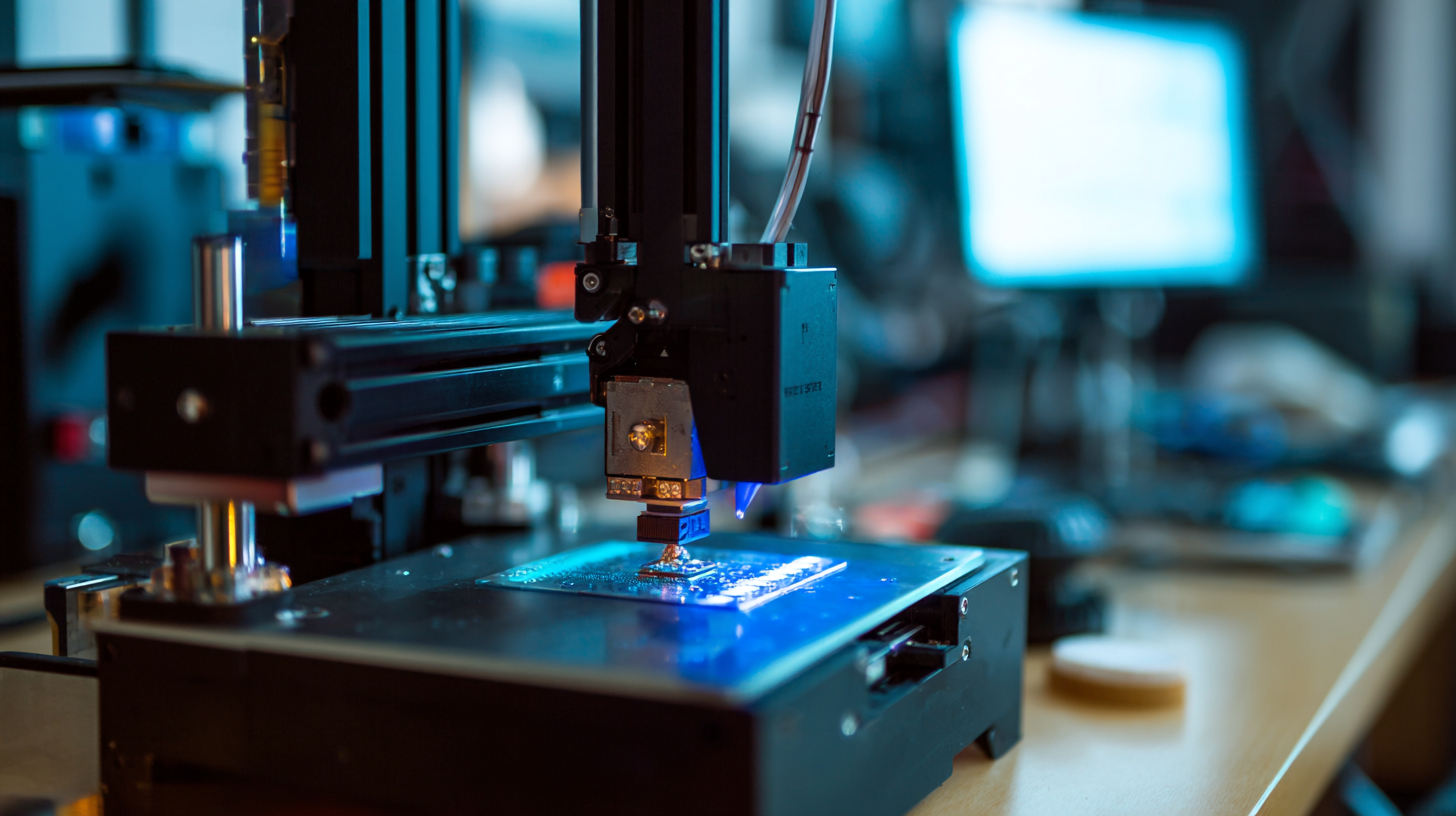

Another important factor to consider is the supplier’s ability to offer innovative technologies and materials. The fast-paced nature of prototyping demands access to the latest advancements in manufacturing processes and materials. Suppliers who invest in cutting-edge technology can enhance the quality of prototypes while ensuring they are produced efficiently. Additionally, evaluating the supplier's quality assurance processes is essential. A robust quality management system guarantees that prototypes meet the required specifications and standards, minimizing the risk of costly revisions later in the development cycle. By focusing on these criteria, businesses can identify suppliers that not only fulfill their immediate needs but also contribute to the long-term sustainability of their projects.

In the pursuit of high-quality fast prototyping solutions, evaluating supplier capabilities is paramount. A recent analysis highlighted that technology and expertise significantly influence supplier performance in the supply chain ecosystem. Specifically, machine capabilities play a critical role; for instance, the adoption of advanced machinery has been shown to improve production efficiency by up to 30%, as noted in industry reports. This translates directly to faster prototyping cycles, which are essential in today’s competitive landscape.

Furthermore, the importance of a robust supplier evaluation model cannot be overstated. An intelligent supplier evaluation model based on data-driven support vector regression has emerged as a pivotal tool for businesses seeking to optimize their supplier selection processes. By leveraging data analytics, companies can assess supplier credit risk more effectively, thereby enhancing resilience within their supply chains. Reports suggest that organizations employing such models can reduce supplier-related disruptions by approximately 25%, enabling them to maintain a steady flow of materials and innovation.

In light of rising global complexities, it’s essential for businesses to not only focus on immediate procurement needs but also to consider long-term supplier health. Initiatives like Supplier Healthiness Assessment Rectification Programs are becoming increasingly vital, as they ensure that suppliers align with sustainability goals while also supporting production capacity needs. This dual focus on technology and supplier wellness is key to navigating the challenges ahead and capitalizing on future opportunities.

Establishing effective communication channels with potential suppliers is crucial when seeking quality fast prototyping solutions. Clear communication helps set expectations and ensures that both parties are aligned on project requirements. One of the most effective ways to enhance communication is by utilizing digital tools such as video conferencing and project management software. These platforms allow for real-time collaboration, making it easier to share design files, discuss project timelines, and address any concerns promptly.

Another key tip is to engage in active listening during discussions. This means not only hearing what the suppliers are saying but also ensuring that their feedback and concerns are acknowledged. Active listening fosters trust and encourages suppliers to share valuable insights that can improve the prototyping process. Additionally, establishing regular check-ins can help maintain momentum and ensure that the project stays on track.

Lastly, don’t underestimate the power of a well-structured follow-up. After initial meetings or discussions, summarizing key points and next steps in an email reinforces understanding and accountability. This practice not only clarifies any misunderstandings but also demonstrates commitment to the partnership, paving the way for a smoother collaboration in creating top-notch prototypes.

When searching for quality suppliers for fast prototyping solutions, conducting thorough supplier audits and assessments is crucial. This process ensures that the selected partners align with your project's standards and can deliver quality products effectively. One essential tip is to establish clear criteria that evaluate suppliers on critical factors such as production capabilities, quality control processes, delivery timelines, and customer service. This will provide a benchmark against which you can measure potential suppliers.

Another valuable approach is to perform site visits to suppliers' facilities. This hands-on assessment allows you to see their operations in action and evaluate their equipment, workflow, and overall working environment. Engaging with team members on the ground can provide further insights into their processes and commitment to quality. Lastly, don’t underestimate the importance of reviewing past client testimonials and case studies; they can give you a clearer picture of a supplier's reliability and performance in real-world scenarios. By integrating these practices into your assessment process, you can better identify suppliers that will meet your fast prototyping needs effectively.

When searching for quality suppliers for fast prototyping solutions, leveraging reviews and testimonials can be a game-changer. Real experiences from previous clients provide valuable insights into a supplier's reliability and the quality of their products. By exploring user-generated content on various platforms, potential buyers can filter out the best options available. Customers often share detailed accounts of their dealings, which can highlight aspects such as communication, lead times, and the overall satisfaction with the prototypes received.

In addition to online reviews, direct testimonials can be particularly impactful. Hearing from businesses that have successfully collaborated with a supplier can instill a sense of trust. It’s beneficial for prospective clients to seek out case studies or detailed narratives that showcase a supplier's ability to meet specific project needs. Engaging with these resources can help assess whether a supplier’s capabilities align with your requirements, ultimately leading to a more informed decision-making process.

Prioritizing reviews and testimonials not only enhances the chances of finding a reliable supplier but also streamlines the prototyping journey, paving the way for innovative product development.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |