As the manufacturing landscape continues to evolve, the demand for efficient and cost-effective solutions remains at the forefront of industry innovation. In 2025, global buyers are on the lookout for cutting-edge strategies that enable them to implement rapid tooling processes seamlessly into their production lines.

Rapid tooling, which focuses on accelerating the prototyping and production stages, has become an essential component in developing high-quality products while optimizing time and resources.

Rapid tooling, which focuses on accelerating the prototyping and production stages, has become an essential component in developing high-quality products while optimizing time and resources.

This comprehensive guide will navigate you through the intricacies of selecting the best rapid tooling solutions tailored to your needs in today’s fast-paced market. With a keen understanding of market trends and technological advances, we aim to empower buyers to make informed decisions that enhance their competitive edge and drive profitability in an increasingly globalized environment.

Rapid tooling has revolutionized the manufacturing landscape by providing innovative solutions that significantly reduce lead times and costs. At its core, rapid tooling encompasses the processes and techniques employed to quickly fabricate molds, dies, and other tooling components. According to the 2021 Rapid Manufacturing Market Report, the global rapid tooling market is expected to reach $2.1 billion by 2026, driven by advancements in additive manufacturing and increasing demand for customized products.

Rapid tooling has revolutionized the manufacturing landscape by providing innovative solutions that significantly reduce lead times and costs. At its core, rapid tooling encompasses the processes and techniques employed to quickly fabricate molds, dies, and other tooling components. According to the 2021 Rapid Manufacturing Market Report, the global rapid tooling market is expected to reach $2.1 billion by 2026, driven by advancements in additive manufacturing and increasing demand for customized products.

Key concepts in rapid tooling include soft tooling and hard tooling. Soft tooling typically utilizes lower-cost materials that allow for faster production times, making it ideal for small batch sizes or prototyping. In contrast, hard tooling employs durable materials for longer production runs, often used in mass manufacturing. A 2022 study published by the International Journal of Advanced Manufacturing Technology highlighted that companies utilizing rapid tooling methods could achieve a 30% reduction in time-to-market, showcasing its critical role in enhancing competitive advantage in today's fast-paced environment. Understanding these concepts is vital for global buyers looking to optimize their production processes and innovate effectively.

Rapid tooling techniques have become essential for various manufacturing processes, enabling faster production timelines and increased flexibility in design. Among these methods, additive manufacturing stands out due to its ability to create complex geometries that would be challenging or impossible to achieve using conventional techniques. This has significant implications for industries ranging from automotive to aerospace, where rapid prototyping can lead to quicker iterations and innovations.

Another noteworthy technique is sand casting, which has been enhanced through the integration of sustainability metrics into its production process. By utilizing a multi-criteria decision-making algorithm, manufacturers can better assess the environmental impact of their operations while still delivering high-quality moulds. This approach not only optimizes resource use but also aligns with growing demands for environmentally responsible manufacturing practices.

Innovations in thin-film deposition technologies further illustrate the evolving landscape of rapid tooling solutions. Advanced techniques are now enabling seamless integration of materials onto various substrates, expanding the possibilities for product functionality and performance. These advancements open up new avenues for rapid prototyping and allow companies to push the boundaries of material application, ensuring they remain competitive in a rapidly changing market.

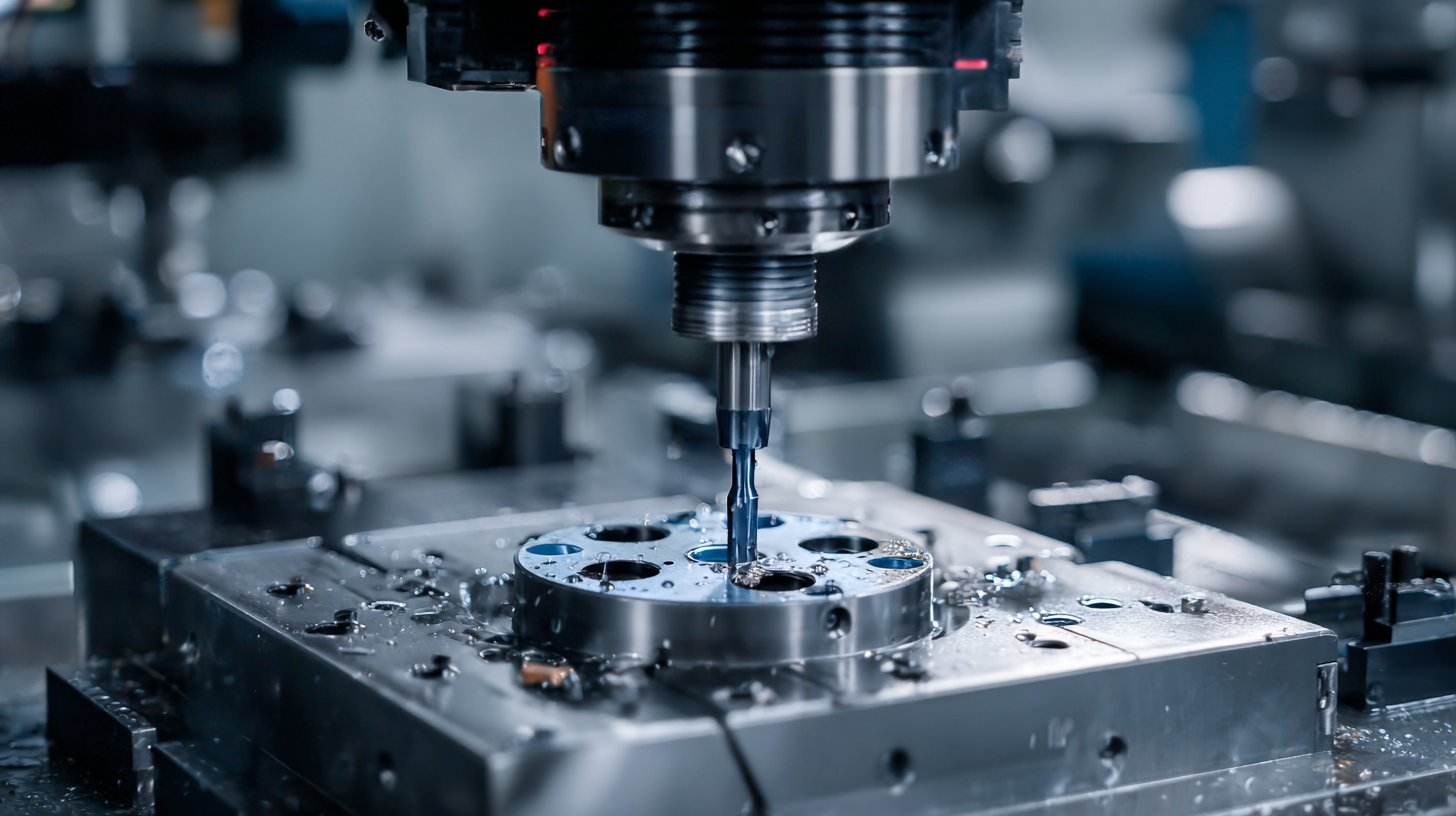

When evaluating rapid tooling solutions, understanding the distinctions between traditional and modern methods is crucial for global buyers. Traditional rapid tooling typically involves subtractive manufacturing techniques, such as CNC machining, where material is precisely removed to create tooling. This method has been a reliable choice for many years, offering precision and durability but often at the cost of longer lead times and higher production costs. For buyers engaged in industries where time-to-market is critical, traditional methods may present challenges regarding speed and cost-effectiveness.

In contrast, modern rapid tooling solutions leverage advanced technologies such as 3D printing and additive manufacturing. These methods allow for quicker iterations, often reducing the time from design to finished prototype drastically. Modern techniques offer greater flexibility in design, enabling the production of complex geometries that would be impossible or too costly to achieve with traditional methods. Furthermore, the ability to rapidly prototype and iterate designs means that companies can respond more swiftly to market demands and innovate faster, ultimately leading to a competitive advantage. As buyers consider their options, weighing these fundamental differences will be essential in selecting the tooling solution that best fits their operational and strategic goals.

When selecting rapid tooling solutions, the choice of materials is critical to achieving optimal performance and cost-effectiveness. Various materials, including metals, plastics, and composites, offer distinct advantages depending on the specific application. For instance, aluminum is often favored for its lightweight properties and excellent machinability, making it ideal for short-run production and prototyping. In contrast, high-performance plastics like ABS and polycarbonate provide higher durability and can withstand extreme conditions, making them suitable for end-use applications.

Moreover, the intended production volume and complexity of the design play significant roles in material selection. For low to medium production runs, softer materials can be more economical, while high-volume projects might benefit from stronger, more resilient materials to ensure longevity and reduced maintenance costs. Additionally, it is essential to consider the compatibility of the selected materials with the tooling process, whether it be CNC machining, 3D printing, or injection molding. By carefully evaluating these factors, global buyers can make informed decisions, leading to enhanced efficiency and success in their rapid tooling endeavors.

| Tooling Solution | Material | Advantages | Applications | Cost Range (USD) |

|---|---|---|---|---|

| SLA (Stereolithography) | Resin | High accuracy, smooth surface finish | Prototyping, small batch production | 100 - 500 |

| SLS (Selective Laser Sintering) | Nylon, Polyamide | Durable, complex geometries | Functional prototypes, end-use parts | 200 - 800 |

| FDM (Fused Deposition Modeling) | PLA, ABS, PETG | Low cost, easy to use | Prototype testing, educational applications | 50 - 300 |

| CNC Machining | Aluminum, Steel, Plastics | Precision, high strength | Production parts, tooling | 300 - 2000 |

| Vacuum Casting | Silicone, Polyurethane | Rapid production, good surface finish | Low-volume production runs | 500 - 1500 |

When it comes to selecting rapid tooling vendors, global buyers must adopt best practices to ensure the highest quality and efficiency. According to a 2021 report by Grand View Research, the global rapid tooling market is projected to reach $2.55 billion by 2028, reflecting a compound annual growth rate (CAGR) of 8.3%. This growth signifies an increasing reliance on specialized vendors who can provide advanced solutions tailored to specific manufacturing needs. Buyers should prioritize vendors with proven track records and industry certifications to ensure they meet stringent quality standards.

Furthermore, it is essential for global buyers to evaluate vendor capabilities by reviewing case studies and client testimonials. A 2022 survey conducted by Deloitte revealed that 67% of manufacturers consider responsiveness and communication critical when choosing a rapid tooling partner. As such, efficient collaboration and transparency in the development process can significantly enhance project outcomes. Buyers should also inquire about the vendor's technologies, such as additive manufacturing and CNC machining, as these can significantly influence both production speed and cost-effectiveness. By focusing on these key areas, global buyers can make informed decisions that align with their production goals.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |